Material Handling Automation Solutions: Reshaping the Supply Chain Landscape

In the present era, businesses are driven by two definitive traits: fast and competitive. Through heightened efficiency and productivity, businesses strive to outcompete their industry peers. As a result, thematic areas of continual improvements are being invaded, one of which is material handling. Material handling refers to the movement, storage, and control of materials. Material movement could occur in the manufacturing, distribution, or logistics processes. Whereas the advancements in automation technology reshape material handling, there are unique solutions that aim to streamline the sector, enabling organizations to optimize service delivery. The essay explores material handling automation by covering its explanation and types of solutions available.

Understanding Material Handling Automation

Material handling automation is the use of automation systems and technologies in human tasks automation sectors. Common systems and solutions utilized in delivering material handling automation include robotics, conveyor systems, automated guided vehicles (AGVs), and warehouse management systems (WMS) . Businesses benefit from material handling automation due to efficiency, accuracy, and scalability while reducing labor costs and errors.

Types of Material Handling Automation Solutions

1. Robotics

Robotics are instrumental in material handling automation, particularly in picking, packing, palletizing, and sorting. Robotics incorporates sensors and advanced vision systems to enable robots in navigating challenging environments and handling products with specific precision and sensitivity. Collaborative robots (cobots) , which work with employees, are increasingly becoming popular in various factories for advanced and flexible assembly.

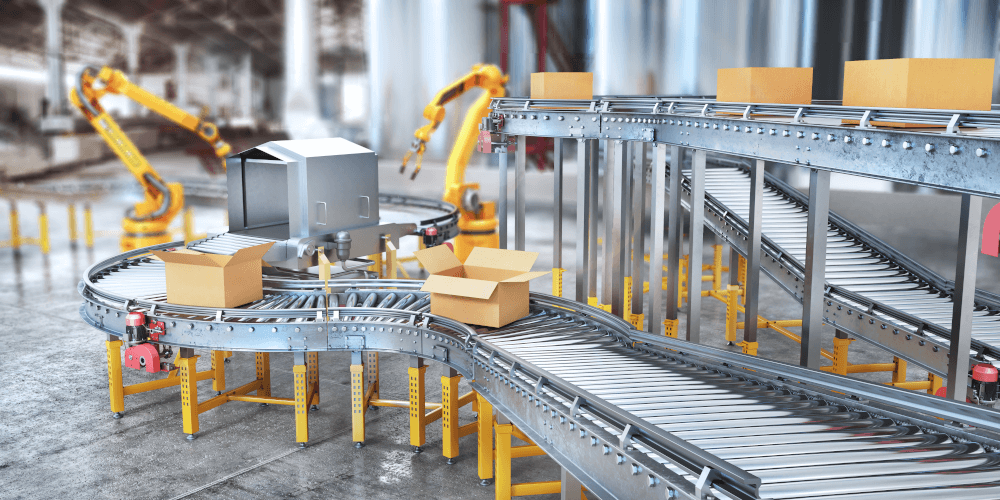

2. Conveyor Systems

The conveyor system is elemental in seamless material movement within a facility or warehouse. The systems include belt conveyors, roller conveyors, and overhead conveyor systems. Businesses deploy such systems based on their throughput requirement and available working space. Proper installation outcome ensures less material handling and substantial efficiency in production and distribution processes.

3. Automated Guided Vehicles (AGVs)

AGVs are self-navigating vehicles equipped with navigation systems and sensors that allow them to transport items and products within a facility without human assistance. They operate on predefined paths and can steer clear of objects in their path while adjusting their pace and trajectory as needed. AGVs are commonly employed in factories, distribution centers and warehouses to automate and boost the efficiency of material movements, restocking and picking, and thus reduce cycle times.

4. Warehouse Management Systems (WMS)

Warehouse management systems (WMS) is a program or suite of programmes used to manage the day-to-day operations of a storage system. Such programs let the user control inventory, pick and fill orders, and coordinate distribution operations. They might offer all or just some of these features by integrating with or accessed through an enterprise resource planning system. WMS systems frequently interact with automation technologies such as bar code readers and radio-frequency identification labels and equipment to maximize the speed of order fulfillment and the accuracy of stored and transported commodities.

Benefits of Material Handling Automation Solutions

1. Increased Efficiency

Material handling automation solutions boost efficiency by eliminating manual labour, reducing errors and optimizing overall flow. Automation of repetitive chores may lead to quicker throughput, shorter cycle times, and more rapid order completion, all of which benefit consumer need and competition.

2. Cost Reduction

Businesses save more money with automation for labour and inventory. Businesses can save money with automation on labor expenses related to moving and storing goods, and on overhead costs associated with warehousing and transport. Businesses can cut expenses and increase revenues by optimizing resource usage and minimizing human effort and workload with automation.

3. Enhanced Safety

Automation enhances workplace safety by reducing the risk of accidents and injuries associated with manual material handling tasks. By delegating hazardous or physically demanding tasks to automated systems, businesses can create safer working environments for their employees and minimize the likelihood of workplace incidents.

4. Scalability and Flexibility

Material handling automation solutions are highly scalable and flexible, easily adjusted to meet shifting business requirements and market conditions. Regardless of whether the business is growing intensively, experiencing seasonal fluctuations or changing the product mix, automation technologies can be scaled up or down to accommodate changing needs, ensuring optimal performance and resource utilization.

Conclusion

In conclusion, material handling automation solutions are transforming the way businesses operate their supply chains, enabling unprecedented levels of efficiency, accuracy, and scalability. By leveraging robotics, conveyor systems, AGVs, and WMS, businesses can enhance their operations, improve efficiency, and save costs. In light of further advancement of automation solutions, it is imperative for businesses to adopt these technologies in order to maintain their position in the dynamic market environment. Material handling automation is more than a trend; it has become a necessity for businesses seeking success in the increasingly competitive and tight market conditions. By investing in automation solutions, firms can guarantee their sustainable performance, improve their competitive edge, and drive growth and innovation.

-

AC Drives (18109)

AC Drives are essential components in modern industrial and commercial motor control systems, offering unparalleled efficiency and flexibility. These drives, also known as Variable Frequency Drives (VFDs), are designed to regulate motor speed and torque, optimizing system performance and reducing energy consumption. AC Drives are widely used in industries such as manufacturing, HVAC, water treatment, and material handling, where precise… -

Butterfly Valve (236)

Butterfly Valves are essential components for flow regulation and isolation in pipelines, offering a compact, efficient, and cost-effective solution. These valves are designed for precision and durability, making them ideal for a wide range of industries, including water treatment, chemical processing, HVAC systems, and power generation. The lightweight and low-maintenance design of Butterfly Valves ensures easy installation and operation, even… -

Circuit Breaker (2226)

Circuit breakers are essential components in electrical systems, offering reliable protection against overloads and short circuits. By automatically interrupting the flow of electricity during faults, circuit breakers prevent potential damage to wiring, equipment, and electrical devices. Whether in residential, commercial, or industrial settings, these safety devices are crucial for maintaining electrical system integrity and preventing fire hazards caused by electrical… -

Contactor (567)

Contactors are essential components used in electrical control systems to connect and disconnect electrical circuits. Often employed in industrial, commercial, and residential applications, contactors are designed for high-frequency switching and are crucial for ensuring the safe operation of various electrical systems. Our Contactors are engineered to provide superior performance, durability, and reliability in controlling heavy-duty electrical loads. Featuring high-quality materials… -

Counter (78)

Counters are essential devices used in various industries to track, monitor, and measure quantities or time intervals. These devices are widely employed in retail environments, industrial settings, and scientific research to provide accurate, real-time data on a wide range of parameters. In industrial applications, counters are often used to monitor production cycles, equipment usage, or inventory counts. Their ability to… -

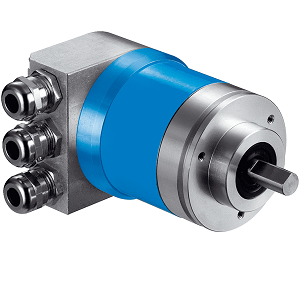

Encoder (117)

Encoders are key components in modern automation, providing essential feedback for precise position, speed, and motion control in a wide range of industrial and robotic applications. These devices convert mechanical motion into electrical signals, allowing systems to accurately monitor and control movements. Encoders are crucial for tasks such as motor control, robotics, CNC machines, and automated production lines. In industrial… -

Fanuc Main Board (1376)

The Fanuc Main Board is a crucial component for ensuring the proper functioning of Fanuc CNC machines, robotic systems, and other automation applications. As the central hub of the control system, the main board facilitates communication between different machine parts, such as the servo motors, drives, and control units, enabling precise and efficient operation. Whether you're operating a CNC lathe,… -

Flow Transmitter (Flow meter) (36)

Flow transmitters and flow meters are critical devices used across industries to measure and control the flow of liquids, gases, and steam. These instruments provide essential data for processes that require accurate flow measurement and regulation, ensuring efficiency, safety, and reliability. Flow meters are widely used in industries such as oil and gas, water treatment, food and beverage, chemical manufacturing,… -

HMI/Touch Screen (587)

Human-Machine Interfaces (HMIs) and Touch Screen Panels are essential tools for bridging the gap between operators and machines, enabling efficient monitoring, control, and optimization of complex systems. These advanced interfaces are widely utilized in industries like manufacturing, automation, energy, healthcare, and transportation. HMIs and touch screen panels offer intuitive, user-friendly designs that simplify the control of equipment, allowing operators to… -

Inverter (959)

Inverters and variable frequency drives (VFDs) are essential components in modern energy management and motor control systems. These technologies enable precise speed and torque control of electric motors, improving energy efficiency and reducing operational costs. Variable frequency drives are widely used in industrial automation, HVAC systems, and manufacturing processes to optimize performance and lower energy consumption. By adjusting motor speed… -

Network/Signal (4)

Network/Signal solutions are critical for establishing and maintaining seamless connectivity in today’s interconnected world. These technologies play an essential role in supporting communication networks, data transfer, and signal processing across diverse industries, including telecommunications, IT, industrial automation, and healthcare. High-quality Network/Signal systems ensure that devices and networks communicate efficiently, enabling faster data exchange, improved reliability, and reduced latency. Whether you're… -

Others (4680)

Industrial automation relies on a seamless integration of components to ensure efficiency, precision, and reliability. Other industrial automation parts play a critical role in complementing core systems by providing support and enabling optimized functionality. These parts encompass a broad spectrum of essential components, including relays, sensors, connectors, actuators, controllers, and more. Designed for diverse industrial environments, they cater to industries… -

Power Supply (218)

An automation power supply is a crucial component in industrial automation systems, providing stable and efficient power to ensure smooth operation of automated machinery, sensors, and control units. These power supplies are designed to meet the specific demands of automation, offering precise voltage regulation, energy efficiency, and long-term reliability. In industrial environments, automation systems rely on power supplies that can… -

Pressure Transmitter (61)

Automation Pressure Transmitters are critical components in industrial automation systems, used to measure and monitor pressure levels in various applications. These transmitters convert pressure readings into standardized electrical signals, which can be used to control and monitor machinery, processes, and systems in real-time. Engineered for accuracy, Automation Pressure Transmitters are designed to handle harsh industrial environments, providing consistent and reliable… -

Programmable Logic Controller (PLC) (6284)

A Programmable Logic Controller (PLC) is a specialized computer designed for controlling industrial processes and machinery. Widely used in manufacturing, energy, and automation industries, PLCs are known for their reliability, durability, and precision in handling automated systems. PLCs play a vital role in industrial automation, providing real-time control over equipment and processes. They are ideal for applications like assembly lines,… -

Relay (927)

Automation relays are critical components in modern industrial systems, offering efficient control, switching, and monitoring of electrical circuits. These devices play a vital role in automating processes, ensuring smooth operations, and improving system reliability across a wide range of industries. Designed for performance and durability, automation relays are ideal for applications in manufacturing, power distribution, and machine automation. They help… -

Sensor (2226)

Temperature sensors are critical devices used across various industries to measure and monitor temperature with precision and reliability. These sensors play a vital role in ensuring optimal performance, safety, and energy efficiency in diverse applications such as industrial automation, HVAC systems, healthcare equipment, and scientific research. Available in various types, including thermocouples, resistance temperature detectors (RTDs), infrared sensors, and thermistors,… -

Servo Motors & Motor Drives (4363)

Servo motors & motor drives are critical components for achieving precision motion control in industrial, automation, and robotics systems. Designed for accuracy, speed, and reliability, these devices are the backbone of applications requiring precise positioning, consistent torque, and real-time feedback. Servo motors offer high-performance control, making them ideal for tasks in CNC machinery, robotics, material handling, and more. They excel… -

Variable Frequency Drives (VFD) (258)

Variable-frequency drive (VFD) or adjustable-frequency drive, variable-voltage/variable-frequency (VVVF) drive, variable speed drive, AC drive, micro drive or inverter drive) is a type of adjustable-speed drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage. VFDs are used in applications ranging from small appliances to large compressors -

Yokogawa Remote Indicators (16)

Yokogawa provides field instruments that measure and display data with a high degree of accuracy. In addition, field mount indicators can be used to remotely monitor data from field instruments installed in difficult-to-access locations: yokogawa remote indicators, digital indicator, loop indicator, field mount indicator