Metal Processing Automation: Revolutionizing the Manufacturing Industry

Metal processing is one of the primary industries in manufacturing. Whether used in automotive, aerospace, construction, or electronics, metal parts are always in demand. With the introduction of automation technologies, metal processing has evolved substantially, opening up new opportunities for higher productivity, accuracy, and innovation. This paper will explore metal processing automation to identify the importance and consequences of this technology for manufacturing.

Understanding Metal Processing Automation

Metal processing automation entails using automated systems and technologies to optimize and simplify the metal fabrication and processing process at various stages, including cutting, forming, welding, machining, and finishing. Both metal-working processes have been revolutionized by automation technologies such as robotics, CNC , and AI-driven systems, enabling manufacturers to produce more efficiently while reducing costs and enhancing product quality.

Key Components of Metal Processing Automation

1. Robotic Welding Systems

Robotic welding systems are essential in metal processing and assembly processes due to their accuracy and efficiency in welding distinct metal components. Equipped with sensors and programming capabilities, these robotic systems can handle complex welding jobs with exceptional accuracy and repeatability. Productivity is enhanced because of robotic welding, and weld quality is consistent, resulting in less reworking and scrap.

2. CNC Machining Centers

Machining centers equipped with CNC technologies are essential elements of metal processing automation. These devices perform precise machining operations in metal production. They are driven by computers that command various cutting instruments. The most crucial benefits are speed, accuracy, and versatility. Manufacturers can now produce extremely complicated components with tight tolerances and intricate geometric shapes.

3. Automated Material Handling Systems

Automated material handling systems Automated material handling systems are used to enhance the movement and storage of raw materials, workpieces, and finished metal products in a processing facility. They include conveyors, AGVs, and robotic arms that haul materials across different processing stations in the manufacturer. Manufacturers can boost their outputs and enhance production processes such as workflow, downtime, and labor cost by automated material handling systems.

4. AI-Powered Quality Control Systems

The AI -powered quality control system determines whether the metal components processed are qualified through machine learning algorithms and computer vision for defect identification and disparities. AI material handling systems help detect surface defects and variations, increasing productivity and decreasing waste.

Benefits of Metal Processing Automation

1. Increased Productivity

The fully automated process reduces production cycle time, the time taken to manufacture a given part, maximizes machine and system uptime, and output volume to meet consumer demand. Metal processing can boost productivity with minimal human intervention, especially in heavy production.

2. Improved Accuracy and Precision

Automated systems employ robotics and CNC machining in the fully automated process, resulting in high accuracy. Without human error and variations, the automated process provides parts with specified tight tolerance and patterns, enhancing part functionality.

3. Cost Reduction

Metal automation process helps manufacturing companies to reduce the cost of labor, production, material, and other indirect and direct material and resources. Automating reduces the cost of production through optimal material use and time and labor.

4. Enhanced Safety

Metal processing automation also contributes to enhanced safety. The use of robots in metalworking decreases the risks of accidents and injuries associated with manual labor in this field. By removing some of the physically demanding and hazardous work steps, manufacturers create a safer working environment for their employees and diminish the likelihood of incidents.

Future Trends in Metal Processing Automation

As automation technology advances, several future trends will shape the landscape of metal processing:

Integration of AI and Machine Learning:

AI and machine learning algorithms becoming more sophisticated will enable predictive maintenance, adaptive machining, and real-time process control.

Additive Manufacturing:

3D printing will become more integrated into the metal processing, enabling new possibilities such as rapid prototyping, individual production, and on-demand manufacturing.

IoT Connectivity:

IoT Connectivity: The Internet of Things will make automation more autonomous by facilitating the connection and data flow between the machines. This will enable remote monitoring, diagnostics, and predictions based on big data analysis.

Conclusion

All of the above showcase that metal processing automation is a revolutionary development that changes the industry in a variety of ways. By using robotic welding systems, CNC machining centers, material handling automation technologies, and AI for quality control, manufacturers improve the processes of metalworking and stay competitive in the contemporary market environment. As automation technologies evolve, companies must implement them to unlock new opportunities provided by innovation in manufacturing. Metal processing automation is no longer just one of the many possible tracks to follow but a critical strategic choice to make for the companies willing to remain competitive and grow in the future.

-

AC Drives (18109)

AC Drives are essential components in modern industrial and commercial motor control systems, offering unparalleled efficiency and flexibility. These drives, also known as Variable Frequency Drives (VFDs), are designed to regulate motor speed and torque, optimizing system performance and reducing energy consumption. AC Drives are widely used in industries such as manufacturing, HVAC, water treatment, and material handling, where precise… -

Butterfly Valve (236)

Butterfly Valves are essential components for flow regulation and isolation in pipelines, offering a compact, efficient, and cost-effective solution. These valves are designed for precision and durability, making them ideal for a wide range of industries, including water treatment, chemical processing, HVAC systems, and power generation. The lightweight and low-maintenance design of Butterfly Valves ensures easy installation and operation, even… -

Circuit Breaker (2226)

Circuit breakers are essential components in electrical systems, offering reliable protection against overloads and short circuits. By automatically interrupting the flow of electricity during faults, circuit breakers prevent potential damage to wiring, equipment, and electrical devices. Whether in residential, commercial, or industrial settings, these safety devices are crucial for maintaining electrical system integrity and preventing fire hazards caused by electrical… -

Contactor (567)

Contactors are essential components used in electrical control systems to connect and disconnect electrical circuits. Often employed in industrial, commercial, and residential applications, contactors are designed for high-frequency switching and are crucial for ensuring the safe operation of various electrical systems. Our Contactors are engineered to provide superior performance, durability, and reliability in controlling heavy-duty electrical loads. Featuring high-quality materials… -

Counter (78)

Counters are essential devices used in various industries to track, monitor, and measure quantities or time intervals. These devices are widely employed in retail environments, industrial settings, and scientific research to provide accurate, real-time data on a wide range of parameters. In industrial applications, counters are often used to monitor production cycles, equipment usage, or inventory counts. Their ability to… -

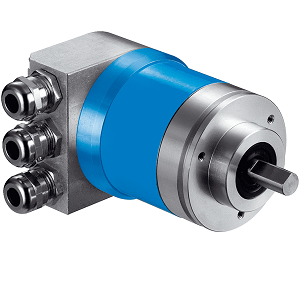

Encoder (117)

Encoders are key components in modern automation, providing essential feedback for precise position, speed, and motion control in a wide range of industrial and robotic applications. These devices convert mechanical motion into electrical signals, allowing systems to accurately monitor and control movements. Encoders are crucial for tasks such as motor control, robotics, CNC machines, and automated production lines. In industrial… -

Fanuc Main Board (1376)

The Fanuc Main Board is a crucial component for ensuring the proper functioning of Fanuc CNC machines, robotic systems, and other automation applications. As the central hub of the control system, the main board facilitates communication between different machine parts, such as the servo motors, drives, and control units, enabling precise and efficient operation. Whether you're operating a CNC lathe,… -

Flow Transmitter (Flow meter) (36)

Flow transmitters and flow meters are critical devices used across industries to measure and control the flow of liquids, gases, and steam. These instruments provide essential data for processes that require accurate flow measurement and regulation, ensuring efficiency, safety, and reliability. Flow meters are widely used in industries such as oil and gas, water treatment, food and beverage, chemical manufacturing,… -

HMI/Touch Screen (587)

Human-Machine Interfaces (HMIs) and Touch Screen Panels are essential tools for bridging the gap between operators and machines, enabling efficient monitoring, control, and optimization of complex systems. These advanced interfaces are widely utilized in industries like manufacturing, automation, energy, healthcare, and transportation. HMIs and touch screen panels offer intuitive, user-friendly designs that simplify the control of equipment, allowing operators to… -

Inverter (959)

Inverters and variable frequency drives (VFDs) are essential components in modern energy management and motor control systems. These technologies enable precise speed and torque control of electric motors, improving energy efficiency and reducing operational costs. Variable frequency drives are widely used in industrial automation, HVAC systems, and manufacturing processes to optimize performance and lower energy consumption. By adjusting motor speed… -

Network/Signal (4)

Network/Signal solutions are critical for establishing and maintaining seamless connectivity in today’s interconnected world. These technologies play an essential role in supporting communication networks, data transfer, and signal processing across diverse industries, including telecommunications, IT, industrial automation, and healthcare. High-quality Network/Signal systems ensure that devices and networks communicate efficiently, enabling faster data exchange, improved reliability, and reduced latency. Whether you're… -

Others (4680)

Industrial automation relies on a seamless integration of components to ensure efficiency, precision, and reliability. Other industrial automation parts play a critical role in complementing core systems by providing support and enabling optimized functionality. These parts encompass a broad spectrum of essential components, including relays, sensors, connectors, actuators, controllers, and more. Designed for diverse industrial environments, they cater to industries… -

Power Supply (218)

An automation power supply is a crucial component in industrial automation systems, providing stable and efficient power to ensure smooth operation of automated machinery, sensors, and control units. These power supplies are designed to meet the specific demands of automation, offering precise voltage regulation, energy efficiency, and long-term reliability. In industrial environments, automation systems rely on power supplies that can… -

Pressure Transmitter (61)

Automation Pressure Transmitters are critical components in industrial automation systems, used to measure and monitor pressure levels in various applications. These transmitters convert pressure readings into standardized electrical signals, which can be used to control and monitor machinery, processes, and systems in real-time. Engineered for accuracy, Automation Pressure Transmitters are designed to handle harsh industrial environments, providing consistent and reliable… -

Programmable Logic Controller (PLC) (6284)

A Programmable Logic Controller (PLC) is a specialized computer designed for controlling industrial processes and machinery. Widely used in manufacturing, energy, and automation industries, PLCs are known for their reliability, durability, and precision in handling automated systems. PLCs play a vital role in industrial automation, providing real-time control over equipment and processes. They are ideal for applications like assembly lines,… -

Relay (927)

Automation relays are critical components in modern industrial systems, offering efficient control, switching, and monitoring of electrical circuits. These devices play a vital role in automating processes, ensuring smooth operations, and improving system reliability across a wide range of industries. Designed for performance and durability, automation relays are ideal for applications in manufacturing, power distribution, and machine automation. They help… -

Sensor (2226)

Temperature sensors are critical devices used across various industries to measure and monitor temperature with precision and reliability. These sensors play a vital role in ensuring optimal performance, safety, and energy efficiency in diverse applications such as industrial automation, HVAC systems, healthcare equipment, and scientific research. Available in various types, including thermocouples, resistance temperature detectors (RTDs), infrared sensors, and thermistors,… -

Servo Motors & Motor Drives (4363)

Servo motors & motor drives are critical components for achieving precision motion control in industrial, automation, and robotics systems. Designed for accuracy, speed, and reliability, these devices are the backbone of applications requiring precise positioning, consistent torque, and real-time feedback. Servo motors offer high-performance control, making them ideal for tasks in CNC machinery, robotics, material handling, and more. They excel… -

Variable Frequency Drives (VFD) (258)

Variable-frequency drive (VFD) or adjustable-frequency drive, variable-voltage/variable-frequency (VVVF) drive, variable speed drive, AC drive, micro drive or inverter drive) is a type of adjustable-speed drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage. VFDs are used in applications ranging from small appliances to large compressors -

Yokogawa Remote Indicators (16)

Yokogawa provides field instruments that measure and display data with a high degree of accuracy. In addition, field mount indicators can be used to remotely monitor data from field instruments installed in difficult-to-access locations: yokogawa remote indicators, digital indicator, loop indicator, field mount indicator