What is Assembly Line Automation?

Assembly line automation refers to the application of machinery, robotics, and computer systems to the process of manufacturing in order to simplify and optimize this process. It is the automation of the performance of repetitive tasks typically done by humans on the assembly line. This approach has fundamentally changed the entire production process, bringing various advantages to businesses in many industries.

Importance of Automation in Manufacturing

In the modern market, efficiency and productivity are the keys to the success of being a company. Assembly line automation contributes to meeting these requirements through enhancing performance efficiency, reducing manufacturing costs, and ensuring product quality. With the help of automation to complete repetitive tasks, manufacturers can perform work more effectively while decreasing the risk of errors and losses. .

Types of Assembly Line Automation

Robotic Assembly

This includes using industrial robots for welding, painting, and assembly. Such robots have sensors that provide very high accuracy and precision. In addition, they possess programming ability, which allows them to perform work with a high degree of consistency.

Conveyor Systems

Conveyor systems include moving components and products along the line. They can be adjusted for materials of various sizes and shapes to ensure seamless running throughout the production facility.

Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) are self-directed vehicles for moving materials and goods from one place to another within an industrial setting. They have control, steering, and position sensors.

Collaborative Robots (Cobots)

These are designed to work collaboratively with humans. In contrast to the use of isolated logistics robots, they can easily be relocated and set up as necessary. In conclusion, the use of manufacturing automation is a very wise decision for any company, regardless of the time and money it invests in it.

Benefits of Automating Your Production Line

While automation may present challenges to certain businesses, several benefits can be derived from automating your production line. Some of these benefits include the following.

Increased Efficiency

Automation of an assembly line increases efficiency by decreasing cycle times and optimizing workflow. In simpler terms, running an automated ship puts a lot less strain on human factors. Therefore, manufacturers can manufacture more products to exact specifications without sacrificing quality.

Reduced Labor Costs

Automation replaces manual labor that is tired, absent, sick, or otherwise limited with more efficient automated systems. There will still be labor, but a company will reduce the costs associated with wages, benefits, and training dramatically. Manufacturers can allocate the saved money to other avenues, such as Pay-Per-Click ads, and be more competitive in terms of marketing.

Improved Product Quality

Products are manufactured to be more consistent and exact when they are manufactured through automation. Quality measures can be automated to shut down production if something is off or different about the product line. That way, manufacturers can address the issue as it happens and only the highest quality products reach the global market.

Enhanced Workplace Safety

Automation also reduces the harm that humans can do to one another. Machines and software-based systems are predictable and controllable, making it possible for more dangerous tasks to be assigned to machines instead of humans. It aids in reducing the number of claims and creating a safer working environment.

Challenges of Assembly Line Automation

While assembly line automation offers numerous benefits, it also presents several challenges that businesses must overcome:

Initial Investment

Implementing assembly line automation requires a significant upfront investment in equipment, technology, and infrastructure. For many businesses, the initial cost of automation can be prohibitive, requiring careful planning and budgeting.

Integration Complexities

Integrating automated systems into existing manufacturing processes can be complex and time-consuming. Businesses must ensure compatibility between new and existing equipment, as well as provide adequate training for employees to operate and maintain automated systems effectively.

Workforce Adaptation

The shift towards automation may require businesses to retrain or reallocate their workforce to accommodate changes in job roles and responsibilities. This can be challenging for employees who are accustomed to traditional methods of production and may resist adopting new technologies.

Future Trends in Assembly Line Automation

As technology continues to evolve, the future of assembly line automation holds exciting possibilities:

Artificial Intelligence Integration

Artificial intelligence (AI) is poised to revolutionize assembly line automation by enabling machines to learn and adapt to changing production demands. AI-powered systems can optimize processes in real-time, making predictive maintenance and quality control more efficient and effective.

Internet of Things (IoT) Connectivity

The Internet of Things (IoT) allows machines and devices to communicate and share data seamlessly. By connecting various components of the manufacturing process, businesses can gain valuable insights into performance, efficiency, and product quality, enabling them to make data-driven decisions and improve overall productivity.

Flexible Automation Solutions

Flexible automation solutions are becoming increasingly popular as businesses seek to adapt to changing market demands and consumer preferences. These systems are designed to be versatile and easily reconfigured to accommodate different products, production volumes, and manufacturing processes.

Conclusion

In conclusion, assembly line automation is a transformative approach to manufacturing that offers significant advantages in terms of efficiency, cost savings, and product quality. By leveraging technologies such as robotics, conveyor systems, and AI, businesses can streamline their production processes and gain a competitive edge in the market. While challenges exist, the future of assembly line automation looks promising, with continued innovation driving improvements in productivity and flexibility.

FAQs (Frequently Asked Questions)

What industries benefit most from assembly line automation?

- Assembly line automation is particularly beneficial for industries with high-volume production requirements, such as automotive, electronics, and consumer goods.

How can small businesses implement assembly line automation?

- Small businesses can start by identifying repetitive tasks that can be automated and gradually invest in scalable automation solutions that align with their production needs and budget.

Are there any risks associated with assembly line automation?

- While assembly line automation offers numerous benefits, risks such as initial investment costs, integration complexities, and workforce adaptation challenges should be carefully considered and addressed.

Can assembly line automation lead to job loss?

- While automation may eliminate some traditional roles, it also creates new opportunities for skilled workers to operate, maintain, and program automated systems, leading to a shift in job roles rather than outright job loss.

How does assembly line automation contribute to sustainability?

- Assembly line automation can lead to reduced energy consumption, waste, and emissions by optimizing production processes and minimizing inefficiencies, thus contributing to a more sustainable manufacturing ecosystem.

-

AC Drives (18111)

AC Drives are essential components in modern industrial and commercial motor control systems, offering unparalleled efficiency and flexibility. These drives, also known as Variable Frequency Drives (VFDs), are designed to regulate motor speed and torque, optimizing system performance and reducing energy consumption. AC Drives are widely used in industries such as manufacturing, HVAC, water treatment, and material handling, where precise… -

Butterfly Valve (236)

Butterfly Valves are essential components for flow regulation and isolation in pipelines, offering a compact, efficient, and cost-effective solution. These valves are designed for precision and durability, making them ideal for a wide range of industries, including water treatment, chemical processing, HVAC systems, and power generation. The lightweight and low-maintenance design of Butterfly Valves ensures easy installation and operation, even… -

Circuit Breaker (2226)

Circuit breakers are essential components in electrical systems, offering reliable protection against overloads and short circuits. By automatically interrupting the flow of electricity during faults, circuit breakers prevent potential damage to wiring, equipment, and electrical devices. Whether in residential, commercial, or industrial settings, these safety devices are crucial for maintaining electrical system integrity and preventing fire hazards caused by electrical… -

Contactor (567)

Contactors are essential components used in electrical control systems to connect and disconnect electrical circuits. Often employed in industrial, commercial, and residential applications, contactors are designed for high-frequency switching and are crucial for ensuring the safe operation of various electrical systems. Our Contactors are engineered to provide superior performance, durability, and reliability in controlling heavy-duty electrical loads. Featuring high-quality materials… -

Counter (78)

Counters are essential devices used in various industries to track, monitor, and measure quantities or time intervals. These devices are widely employed in retail environments, industrial settings, and scientific research to provide accurate, real-time data on a wide range of parameters. In industrial applications, counters are often used to monitor production cycles, equipment usage, or inventory counts. Their ability to… -

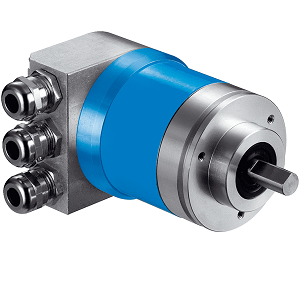

Encoder (117)

Encoders are key components in modern automation, providing essential feedback for precise position, speed, and motion control in a wide range of industrial and robotic applications. These devices convert mechanical motion into electrical signals, allowing systems to accurately monitor and control movements. Encoders are crucial for tasks such as motor control, robotics, CNC machines, and automated production lines. In industrial… -

Fanuc Main Board (1376)

The Fanuc Main Board is a crucial component for ensuring the proper functioning of Fanuc CNC machines, robotic systems, and other automation applications. As the central hub of the control system, the main board facilitates communication between different machine parts, such as the servo motors, drives, and control units, enabling precise and efficient operation. Whether you're operating a CNC lathe,… -

Flow Transmitter (Flow meter) (36)

Flow transmitters and flow meters are critical devices used across industries to measure and control the flow of liquids, gases, and steam. These instruments provide essential data for processes that require accurate flow measurement and regulation, ensuring efficiency, safety, and reliability. Flow meters are widely used in industries such as oil and gas, water treatment, food and beverage, chemical manufacturing,… -

HMI/Touch Screen (587)

Human-Machine Interfaces (HMIs) and Touch Screen Panels are essential tools for bridging the gap between operators and machines, enabling efficient monitoring, control, and optimization of complex systems. These advanced interfaces are widely utilized in industries like manufacturing, automation, energy, healthcare, and transportation. HMIs and touch screen panels offer intuitive, user-friendly designs that simplify the control of equipment, allowing operators to… -

Inverter (960)

Inverters and variable frequency drives (VFDs) are essential components in modern energy management and motor control systems. These technologies enable precise speed and torque control of electric motors, improving energy efficiency and reducing operational costs. Variable frequency drives are widely used in industrial automation, HVAC systems, and manufacturing processes to optimize performance and lower energy consumption. By adjusting motor speed… -

Network/Signal (4)

Network/Signal solutions are critical for establishing and maintaining seamless connectivity in today’s interconnected world. These technologies play an essential role in supporting communication networks, data transfer, and signal processing across diverse industries, including telecommunications, IT, industrial automation, and healthcare. High-quality Network/Signal systems ensure that devices and networks communicate efficiently, enabling faster data exchange, improved reliability, and reduced latency. Whether you're… -

Others (4679)

Industrial automation relies on a seamless integration of components to ensure efficiency, precision, and reliability. Other industrial automation parts play a critical role in complementing core systems by providing support and enabling optimized functionality. These parts encompass a broad spectrum of essential components, including relays, sensors, connectors, actuators, controllers, and more. Designed for diverse industrial environments, they cater to industries… -

Power Supply (218)

An automation power supply is a crucial component in industrial automation systems, providing stable and efficient power to ensure smooth operation of automated machinery, sensors, and control units. These power supplies are designed to meet the specific demands of automation, offering precise voltage regulation, energy efficiency, and long-term reliability. In industrial environments, automation systems rely on power supplies that can… -

Pressure Transmitter (61)

Automation Pressure Transmitters are critical components in industrial automation systems, used to measure and monitor pressure levels in various applications. These transmitters convert pressure readings into standardized electrical signals, which can be used to control and monitor machinery, processes, and systems in real-time. Engineered for accuracy, Automation Pressure Transmitters are designed to handle harsh industrial environments, providing consistent and reliable… -

Programmable Logic Controller (PLC) (6284)

A Programmable Logic Controller (PLC) is a specialized computer designed for controlling industrial processes and machinery. Widely used in manufacturing, energy, and automation industries, PLCs are known for their reliability, durability, and precision in handling automated systems. PLCs play a vital role in industrial automation, providing real-time control over equipment and processes. They are ideal for applications like assembly lines,… -

Relay (927)

Automation relays are critical components in modern industrial systems, offering efficient control, switching, and monitoring of electrical circuits. These devices play a vital role in automating processes, ensuring smooth operations, and improving system reliability across a wide range of industries. Designed for performance and durability, automation relays are ideal for applications in manufacturing, power distribution, and machine automation. They help… -

Sensor (2228)

Temperature sensors are critical devices used across various industries to measure and monitor temperature with precision and reliability. These sensors play a vital role in ensuring optimal performance, safety, and energy efficiency in diverse applications such as industrial automation, HVAC systems, healthcare equipment, and scientific research. Available in various types, including thermocouples, resistance temperature detectors (RTDs), infrared sensors, and thermistors,… -

Servo Motors & Motor Drives (4363)

Servo motors & motor drives are critical components for achieving precision motion control in industrial, automation, and robotics systems. Designed for accuracy, speed, and reliability, these devices are the backbone of applications requiring precise positioning, consistent torque, and real-time feedback. Servo motors offer high-performance control, making them ideal for tasks in CNC machinery, robotics, material handling, and more. They excel… -

Variable Frequency Drives (VFD) (258)

Variable-frequency drive (VFD) or adjustable-frequency drive, variable-voltage/variable-frequency (VVVF) drive, variable speed drive, AC drive, micro drive or inverter drive) is a type of adjustable-speed drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage. VFDs are used in applications ranging from small appliances to large compressors -

Yokogawa Remote Indicators (16)

Yokogawa provides field instruments that measure and display data with a high degree of accuracy. In addition, field mount indicators can be used to remotely monitor data from field instruments installed in difficult-to-access locations: yokogawa remote indicators, digital indicator, loop indicator, field mount indicator